FILM EXTRUSION

Companies that operate in the film extrusion sector have increasing need of blending different types of materials to make their products more suited to market demands.

For technical and economical reasons, the preparation of these blends of materials requires a high precision level since the accuracy of the proportions of the components allows:

to supply the client with a finished product that corresponds exactly to his specifications

to monitor production costs, especially in consideration of the high cost of some additives and colorants.

For the gravimetric dosage systems, Plasco offers the grams/meter control since there is the need of monitoring the thickness of the final product, especially when the production consists in co-extruded products in which it is essential to have the precise control of the percentage distribution of each layer.

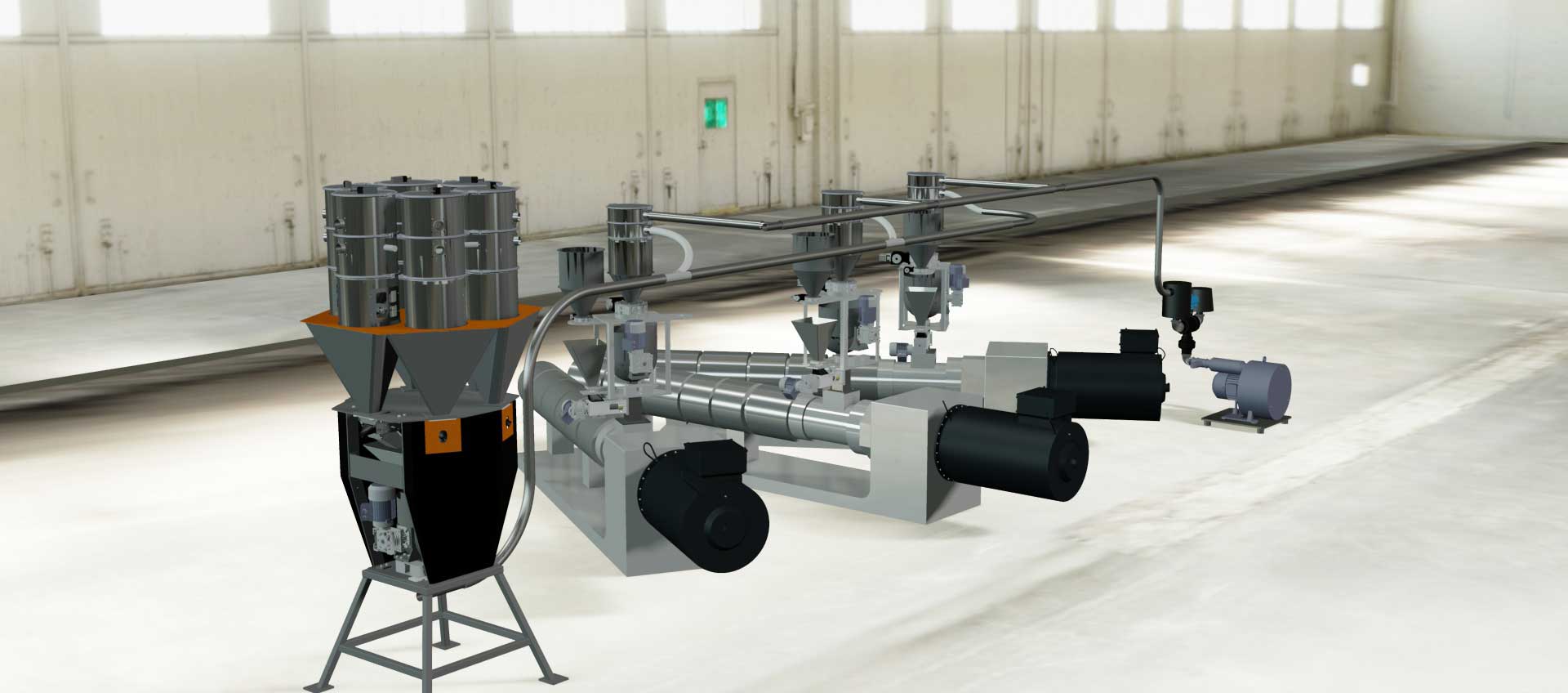

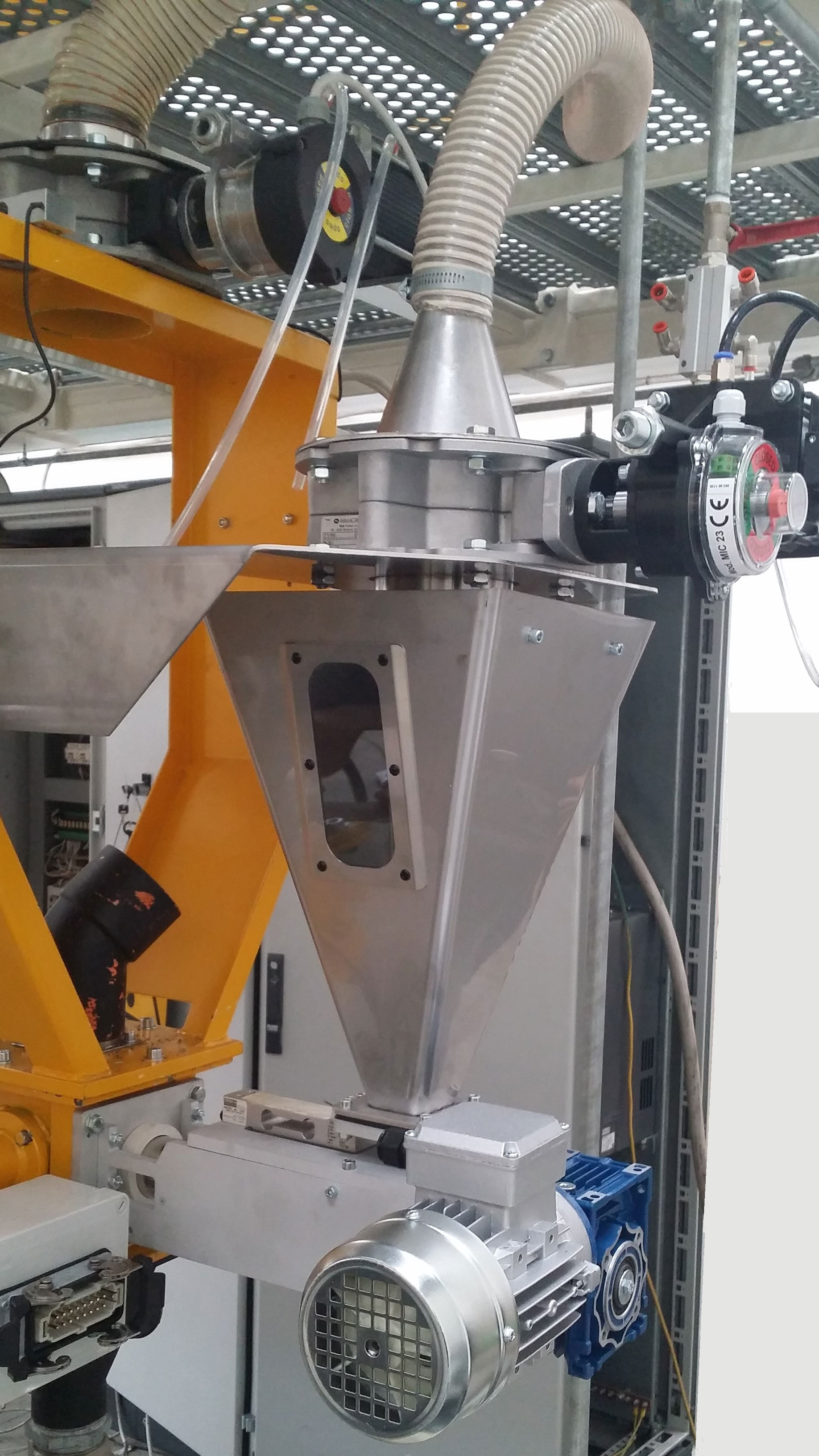

For this sector, where material is used mainly in granule form, Plasco offers following equipment:

| VOLUMETRIC | GRAVIMETRIC |

|---|---|

|

DVG – dosage unit |

BLW – loss-in-weight scale |

|

MVG – mixer |

GLW – loss-in-weight dosage unit |

|

GRAVI – batch system |

GRAMS/METER CONTROL

This control system, supplied with gravimetric systems, allows to adjust extruder and take-off unit speed (or take-off unit alone) in order to maintain constant the weight per linear meter of the extruded product.

The operator sets the values that define the features of the finished product on the control system (gram/mt. and mt/minute or width, thickness and specific weight, in case of film).

Once the automatic functioning mode has been selected, the system acquires the control of the speed of the extruder and take-off unit and maintains constant the production values set.

This type of control can be applied to gravimetric systems GRAVI (batch) and BLW (loss-in-weight).